All Categories

Featured

Table of Contents

- – Rv Rubber Roof Maintenance Tustin, CA

- – OCRV Center

- – Rv Slide Out Roof Repair Tustin, CA

- – Rv Rubber Roof Maintenance Tustin, CA

- – Resealing Rv Roof Tustin, CA

- – Roof Repair For Rv Tustin, CA

- – Rv Roof Repair Tustin, CA

- – Rv Roof Replacement Tustin, CA

- – Rubber Roof For Camper Tustin, CA

- – Epdm Rv Roof Repair Tustin, CA

- – Rubber Roofing For Campers Tustin, CA

- – Rv Rubber Roof Maintenance Tustin, CA

- – Replace Rv Roof Tustin, CA

- – Rubber Roof Installation Tustin, CA

- – Repair Rv Roof Tustin, CA

- – OCRV Center

Rv Rubber Roof Maintenance Tustin, CA

Roof coverings specifically have a great deal of prospective leakage areas. Examining around screws and at joints is important to maintaining water from obtaining right into the walls and causing delamination. Bear in mind to have the proper sealants on hand. A roof covering joint and the area around a screw may require various roof sealers.

Some windows aren't entirely secured, but it's still important to maintain the seals that are needed. Walk around your whole Recreational vehicle and check every area of change or penetration.

Make it a priority to recognize where you have motor home sealers and what locations are at threat for cracks and various other damage. Being acquainted with the area of every one of your sealants makes your sealant check both quick and efficient. Doing that detailed check (it can take as little as 15 minutes) two times a year can save you from the inconvenience and expenditure of a major water damage fixing.

Rv Slide Out Roof Repair Tustin, CA

A leaky roofing system is perhaps one of the most relentless problem for numerous Recreational vehicles. Whether it's triggered by falling branches, freezing water, or a few other resource, it appears that water always locates its way right into Recreational vehicles. However, water and RVs were not implied to cohabit, and also a tiny leak can cause tragic repercussions in your motor home - Rubber Roof For Rv Tustin.

It's all also typical to really feel the drip of a leaking roof in your Recreational vehicle. Openings and leaks can occur when heat from the sunlight creates the roofing product to warp or soften.

Rv Rubber Roof Maintenance Tustin, CA

No matter just how the leakage takes place, as soon as water enters your trailer, the issues will truly start. Even little amounts of water can supply the perfect environment for mold and mildew and mold to thrive. If your motor home isn't well-ventilated, the mold will swiftly spread and take over. This is why many older campers have a particular moldy smell - Rubber Roof For Rv Tustin.

There are numerous different products on the market, from silicone sealants to tar products, and which item you choose will certainly depend on the roof material of your trailer. Laundry the whole roof of your RV to remove any debris, tree sap, dirt, and various other pollutants.

Mix up a pail of water with a mild cleaning agent (like dishwashing fluid) and use with the brush. Once the area is tidy and dry, locate the trouble location.

Resealing Rv Roof Tustin, CA

Including this safety barrier will aid avoid any type of future leakages. At the end of the day, roofing repair service is often best left to the professionals.

They'll be able to diagnose the extent of any kind of damages created by the leakage prior to you captured. Plus, you'll be able to have the tranquility of mind knowing the work was done. Bring your leaky RV by The Outpost motor home and speak with our team of seasoned recreational vehicle professionals.

Keep reading to discover some of the methods you can determine and fix recreational vehicle roof leaks. Uncertain exactly how to get going? Right here's a step-by-step overview I mapped out that I desire somebody had actually given me when I began my RV trip. When it pertains to motor home repair and maintenance, the roof should always be examined carefully and regularly.

Roof Repair For Rv Tustin, CA

Since your motor home roof covering is clean, you prepare to seal! Before getting began, it's vital to note that when it comes to Motor home roof covering leakages, there isn't a one dimension fits all solution. Each leak is special and depending on its size and area, it may require a specific type of repair.

RV Roofing System Leak Repair Work: Emergencies Benefits: Can be used on a wet surface, making it excellent for a quick solution for smaller leakages during or after a storm. Pro Tip: Ensure to utilize adequate tape to conceal the opening or gap totally, leaving about an inch of tape right around the damaged area to obtain the most effective protection.

Rv Roof Repair Tustin, CA

Motor Home Roofing Drip Repair Work: Targeting Details Locations Benefits: Great for a longer-term option. Generally used around vents and various other joints that need resealing. Pro Suggestion: Hold the can at a 45-degree angle and use straight to the trouble location being dealt with. Flex Shot takes about 24-48 hours to cure and need to be applied on a dry surface area.

Pro Tip: Prior to utilizing this item, you'll want to make sure the surface area is completely dry. Be certain to appropriately evaluate it on a tiny area first prior to using it on a big surface.

Use appropriate security equipment like gloves and protective glasses as required. Use painter's tape and cover the areas you wish to prevent finish, specifically hinges and other relocating components. While no RV roof covering lasts permanently, appropriate maintenance is crucial for its long life. With normal assessment and the power of The Flex Seal Household of Products, you can assist prolong your recreational vehicle roofing's life and keep it going strong as you enjoy the fantastic outdoors.

Asen is a full-time motor home vacationer because 2018 and is the owner of the blog site, Camper Life. He enjoys outdoor camping in nature, fishing, and investing time with his family members. Aiming to give the most beneficial details regarding campers and Recreational vehicles, he shares every little thing he learned for many years.

Rv Roof Replacement Tustin, CA

Evaluating the roofing system entails very closely checking out the whole surface area, consisting of joints, vents, skylights, and any type of other roofing system parts. This aids in discovering fractures, leaks, tears, or indications of wear and wear and tear. Rubber Roof For Rv Tustin. Roof Covering Cleaning and Preparation: Before performing repairs, the roofing must be completely cleaned to remove dirt, debris, and any type of loosened or broken material

Fixing Leakages: Water leakages are a typical trouble in Motor home roofings and ought to be addressed without delay. Frequently used sealants consist of silicone-based items or specialized Recreational vehicle roof covering sealers that are suitable with the roofing system material.

Patching involves using repair service tape, spots, or layers to cover small locations of damage, while substantial damages might require changing larger areas of the roof covering product. The replacement material ought to match the initial roofing product to guarantee correct fit and resilience. Securing and Coating: Using a safety roofing sealer or covering is essential to improve the longevity and water resistance of the roof.

Entertainment automobiles (Recreational vehicles) are a preferred way to travel, as they provide the liberty of the open road with the comforts of home. Recreational vehicles require upkeep simply like any various other car, and one of the most common concerns is a leaking roof. In this short article, we'll review why motor home roofing leaks are a trouble and exactly how to fix them.

Rubber Roof For Camper Tustin, CA

Here are some of one of the most usual problems that can occur from a leaking motor home roofing: One of the most obvious problem that can occur from a dripping roofing system is water damage. Water can permeate right into the wall surfaces, floors, and ceilings of the recreational vehicle, creating mold, mold, and rot. If left uncontrolled, water damage can jeopardize the architectural integrity of the motor home and cause expensive repair work.

Mold and mildew can trigger wellness problems for those who invest time in the Recreational vehicle. If you determine to market your Motor home, a leaking roofing system will considerably reduce its resale worth.

Currently that we've discussed why motor home roofing system leakages are a problem, allow's check out exactly how to fix them. There are several actions you can require to fix a dripping recreational vehicle roofing system, depending upon the intensity of the damage. The initial step in dealing with a dripping recreational vehicle roof is identifying where the water is coming from.

Once you have actually identified the resource of the leak, you'll require to clean and prepare the location for repair service. Use a cleaner specifically created for RV roofings to guarantee that the surface is tidy and totally free of impurities.

Epdm Rv Roof Repair Tustin, CA

Utilize a high-grade sealer that's created for motor home roofings and works with the existing sealant. Apply the sealant in a smooth, also layer, and make sure to cover the entire damaged area. After applying the sealant, permit it to completely dry completely prior to exposing it to water. Adhere to the producer's guidelines for drying out time, but in basic, you need to wait a minimum of 24-hour before examining the repair work.

Examine inside the motor home for any type of indications of water invasion, and make any kind of necessary adjustments to the fixing. The most effective means to take care of RV roof covering leaks is to avoid them from occurring to begin with. Here are some suggestions to aid you prevent motor home roofing leaks: Inspect your motor home roof covering on a regular basis for any type of indications of damage or wear.

Rubber Roofing For Campers Tustin, CA

Keep your RV roof clean and complimentary of debris. On a regular basis clean the roof with a cleaner particularly designed for motor home roofings. If you do discover a leak, address it right away. Don't await it to intensify, as the damage will just become extra extreme and expensive to repair. Recreational vehicle roof leakages are an usual problem that can trigger significant damage to your vehicle.

Nothing damages a RV experience quicker than a leaky roofing. Water can create significant damages to the inside of your motor home, as well as every one of your personal belongings. While a recreational vehicle roofing system leak can be a challenging task to take on, you can quickly repair it on your own with the right tools and products.

Rv Rubber Roof Maintenance Tustin, CA

Don't allow a leaking roof destroy your experience - obtain started on your Motor home roofing repair work today! Before you start your Motor home roofing system fixing, it's essential to make sure you have the right devices and materials.

Next off, use the 100% Silicone Motor Home Roof covering Finishing to seal your whole roof. You may wish to make use of a container with a tilted pour spout to spread out the layer in areas that you use a roller or a brush on to move the product around. You'll preferably want 2 thick layers for ideal defense.

Replace Rv Roof Tustin, CA

When you've fixed a motor home roofing system leak, it's essential to take steps to avoid future leakages. Among the finest ways to do this is to keep your roofing system clean and devoid of particles. Ensure to check your roof covering frequently for any kind of damages or particles. It's also vital to check the seals around vents and various other openings.

Last however not the very least, make sure to check the roof covering after any severe weather condition. High winds, hail storm, or heavy rainfalls can all create damages to the roof.

Always seek advice from a specialist prior to embarking on roofing repair work. There are only two types of Motor homes: those with roofing system leaks and those that aren't leaking yet. Keeping your roof covering clean and appropriately maintained will aid. Still, no quantity of upkeep will certainly avert the opportunity of roofing leaks. When we bought our toy hauler, I was thrilled to get a motor home with a strong light weight aluminum roofing system because, apparently, aluminum roofs never leak.

Rubber Roof Installation Tustin, CA

It leakages, and about annually, I discover myself atop a tall ladder on the quest for the latest leak, equipped with a caulk gun and much frustration. Actually, motor home roof coverings take a beating from the components and the roughness of being pulled around the country at freeway speeds.

Don't be the person that brings a caulk weapon onto the roof covering and seals over every joint and infiltration prior to performing a detailed examination. The initial point to look for is noticeable damage in the area over where the leakage occurred.

Repair Rv Roof Tustin, CA

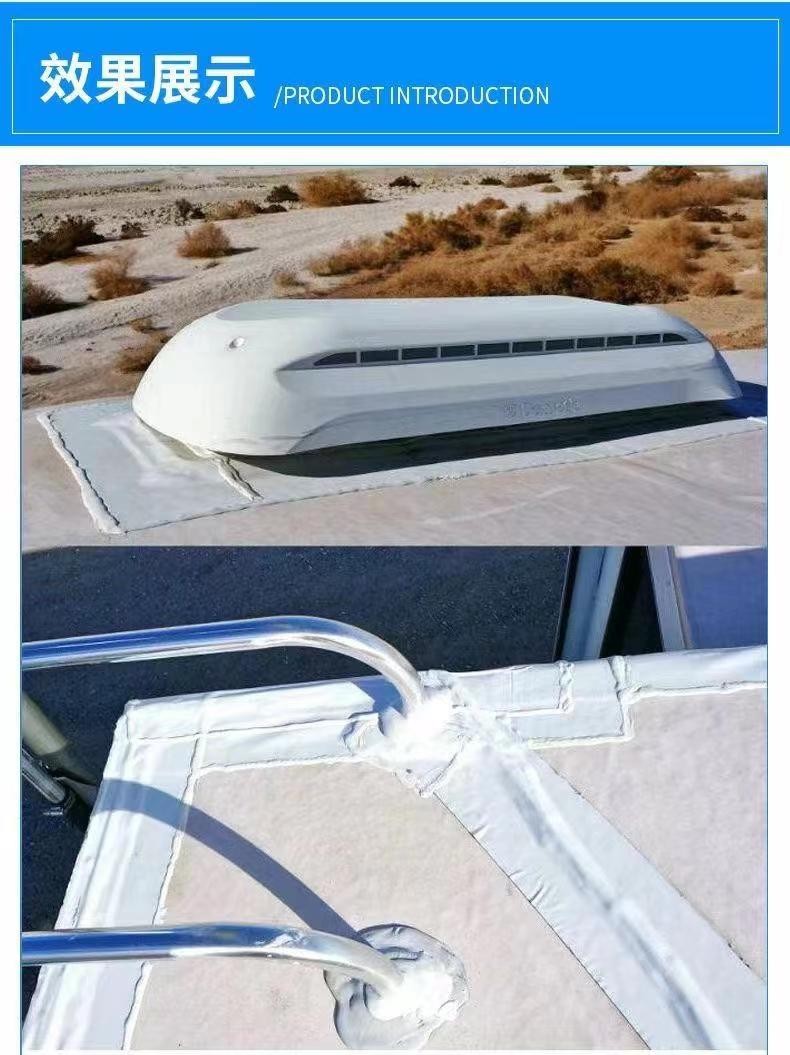

If you don't see anything undoubtedly incorrect, concentrate on the seams and infiltrations. The seams are the edges and joints where the primary straight expanse of your roof connects to the upright wall surfaces on all four sides. The roofing system infiltrations include the rooftop air conditioner systems, skylights, plumbing vent pipelines, antennas, and exhaust followers.

In enhancement to examining the joints, I advise examining any marker lights (Also known as operating lights) on the RV. These are generally small orange or red lights along the top of the exterior walls of the Motor home.

Photo credit rating: rain2shine ventures The scope of the damages and scale of essential repair services are the most effective indicators of what to do next. Based upon your degree of expertise, experience, and ability, consider what requires to be done and if you can do it safely. Leaning off of ladders and walking about on shaky motor home roofing systems isn't a fantastic selection for everybody, and it's best to work with a pro if you have any type of doubts.

Rubber Roofing For Rv Tustin, CAMotorhome Roof Replacement Tustin, CA

Rubber Roofing For Campers Tustin, CA

Rv Roof Leak Repair Near Me Tustin, CA

Rv Roof Leak Repair Near Me Tustin, CA

Rubber Roofing For Rv Tustin, CA

Rv Roof Replacement Tustin, CA

Class C Rv Roof Repair Tustin, CA

Rv Rubber Roof Repair Tustin, CA

Motorhome Roof Replacement Tustin, CA

Rv Roof Repair Fiberglass Tustin, CA

Repair Rv Roof Tustin, CA

Rv Rubber Roof Repair Tustin, CA

Rv Slide Out Roof Repair Tustin, CA

Motorhome Roof Replacement Tustin, CA

Resealing Rv Roof Tustin, CA

Epdm Rv Roof Repair Tustin, CA

Rv Rubber Roof Replacement Cost Tustin, CA

Rv Roof Replacement Tustin, CA

Class C Rv Roof Repair Tustin, CA

Rv Rubber Roof Replacement Tustin, CA

Rubber Roof Installation Tustin, CA

Class C Rv Roof Repair Tustin, CA

Resealing Rv Roof Tustin, CA

Rubber Roof Installation Tustin, CA

Rv Rubber Roof Replacement Tustin, CA

Rubber Roof For Rv Tustin, CA

Repair Rv Roof Tustin, CA

Rv Fiberglass Roof Repair Tustin, CA

Rv Rubber Roof Repair Tustin, CA

Repair Rv Roof Tustin, CA

Rv Trailer Roof Repair Tustin, CA

Rv Trailer Roof Repair Tustin, CA

Rv Trailer Rubber Roof Repair Tustin, CA

Rv Roof Leak Repair Tustin, CA

Best Rv Roof Repair Tustin, CA

Rubber Roof Installation Tustin, CA

Rv Roof Repair Service Near Me Tustin, CA

Rv Rubber Roof Maintenance Tustin, CA

Replace Rv Roof Tustin, CA

Rv Roof Leak Repair Near Me Tustin, CA

Rv Rubber Roof Replacement Tustin, CA

Rv Roof Leak Repair Tustin, CA

Epdm Rv Roof Repair Tustin, CA

Rv Roof Leak Repair Near Me Tustin, CA

Rv Trailer Rubber Roof Repair Tustin, CA

Rv Roof Repair Service Near Me Tustin, CA

Rv Fiberglass Roof Repair Tustin, CA

Resealing Rv Roof Tustin, CA

Roof Repair For Rv Tustin, CA

Repair Rv Roof Leak Tustin, CA

Rv Fiberglass Roof Repair Tustin, CA

Rv Fiberglass Roof Repair Tustin, CA

Rv Rubber Roof Replacement Tustin, CA

Motorhome Roof Replacement Tustin, CA

Roof Repair For Rv Tustin, CA

Rv Roof Replacement Tustin, CA

Rv Trailer Roof Repair Tustin, CA

Rv Slide Out Roof Repair Tustin, CA

Rv Roof Leak Repair Tustin, CA

Rv Trailer Roof Repair Tustin, CA

Rubber Roofing For Campers Tustin, CA

Rv Roof Repair Service Near Me Tustin, CA

Rubber Roofing For Campers Tustin, CA

Rv Roof Replacement Tustin, CA

Rubber Roof For Rv Tustin, CA

Repair Rv Roof Tustin, CA

Rv Trailer Rubber Roof Repair Tustin, CA

Replace Rv Roof Tustin, CA

Class C Rv Roof Repair Tustin, CA

Class C Rv Roof Repair Tustin, CA

Rubber Roof For Rv Tustin, CA

Repair Rv Roof Leak Tustin, CA

Rv Fiberglass Roof Repair Tustin, CA

Rv Trailer Roof Repair Tustin, CA

Rv Trailer Roof Repair Tustin, CA

Rubber Roof For Rv Tustin, CA

Class C Rv Roof Repair Tustin, CA

In Seo Agencies Tustin, CA

Best Seo Marketing Company Tustin, CA

OCRV Center

Table of Contents

- – Rv Rubber Roof Maintenance Tustin, CA

- – OCRV Center

- – Rv Slide Out Roof Repair Tustin, CA

- – Rv Rubber Roof Maintenance Tustin, CA

- – Resealing Rv Roof Tustin, CA

- – Roof Repair For Rv Tustin, CA

- – Rv Roof Repair Tustin, CA

- – Rv Roof Replacement Tustin, CA

- – Rubber Roof For Camper Tustin, CA

- – Epdm Rv Roof Repair Tustin, CA

- – Rubber Roofing For Campers Tustin, CA

- – Rv Rubber Roof Maintenance Tustin, CA

- – Replace Rv Roof Tustin, CA

- – Rubber Roof Installation Tustin, CA

- – Repair Rv Roof Tustin, CA

- – OCRV Center

Latest Posts

Rancho Penasquitos Tankless Water Heater Installation

Tankless Water Heater Installers Tierrasanta San Diego

Plumbing Slab Leak Scripps Ranch San Diego

More

Latest Posts

Rancho Penasquitos Tankless Water Heater Installation

Tankless Water Heater Installers Tierrasanta San Diego

Plumbing Slab Leak Scripps Ranch San Diego